Soil Freezing

Soil freezing is a technique for temporary soil reinforcement by creating an ice-soil structure in the ground. The concept is to convert pure water into ice. Freezing is obtained by circulation of liquid nitrogen or brine in closed pipes placed in the ground, or by a combination of both methods. BAUER Spezialtiefbau GmbH owns a high level knowhow and worldwide experience in the various ground freezing fi elds. Frozen ground may be used to create solid, load resistant and watertight structures for tunneling works, cross passages between tunnels, pits and shaft excavations and TBM break-in or rescue.

There are two different freezing methods which can be used for soil freezing. The direct method is freezing with liquid nitrogen (lN2). This method takes a short freezing time but it has high energy and maintenance costs. The indirect method is freezing with liquid brine, which offers low energy and maintenance costs. It takes around 20 to 30 days for freezing the ground – but this method is also suitable for confi ned spaces. The so-called mixed method is a combination of freezing with liquid nitrogen and brine.

Media

Further interesting information

Types of Construction Method

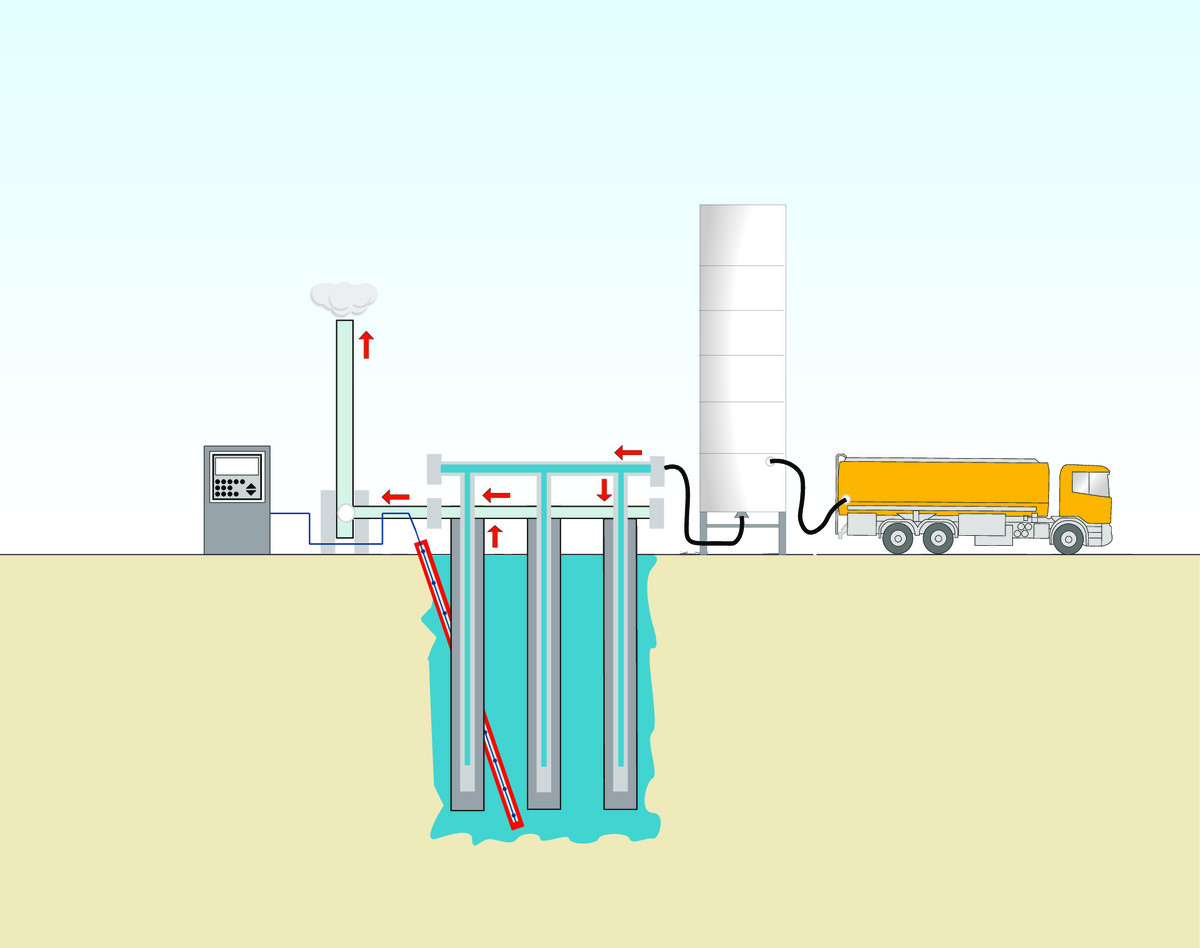

Nitrogen is maintained in a liquid state in an insulated tank slightly above the atmospheric pressure. At a temperature of -196 °C the fluid circulates in copper pipes installed in the ground and freezes the soil around the pipes. The exhausted gas is released into the atmosphere. Under normal conditions, freezing of a soil body is completed within 5 to 8 days. A system of temperature measuring points allows for monitoring of the freezing process and optimization of nitrogen consumption

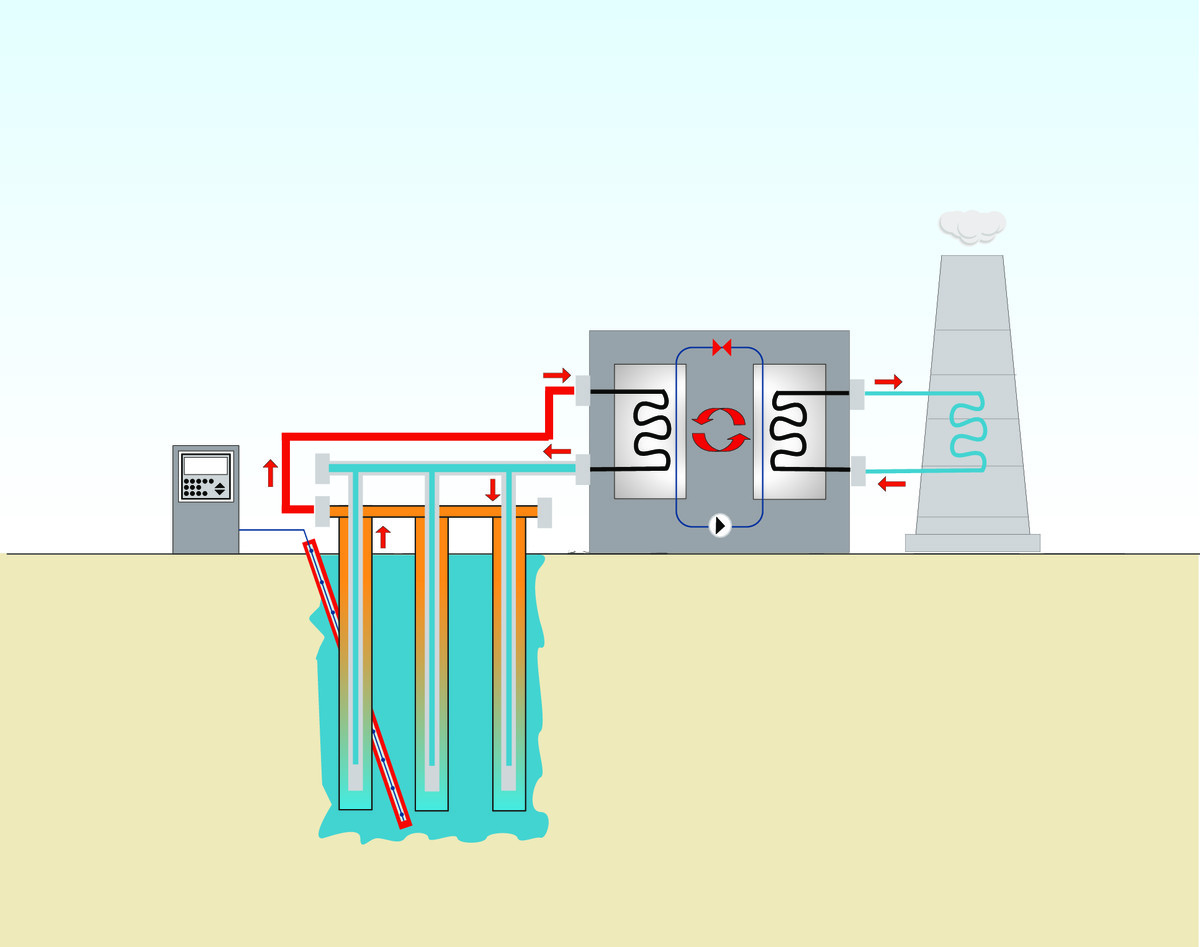

Brine is a nearly 30% solution of calcium chloride in water. Brine is circulated into the ground inside low carbon steel pipes forming a closed circuit between the pipes and the freezing plant. It circulates at a temperature of approx. -35 to -38 °C under normal conditions, freezing of a soil body is completed within 20 to 30 days. A system of temperature measuring points allows for monitoring of the freezing process

The so-called mixed method uses he liquid nitrogen for the freezing phase and the brine for the maintenance phase. It saves time for the freezing phase compared to the brine method. On the other hand it can be quite expensive, since it requires the installation of a separate distribution system for both brine and liquid nitrogen and the use of copper pipes inside the steel freezing pipes. After the nitrogen freezing phase, the temperature of the copper pipes needs to be above -35 °C for the liquid brine to circulate, otherwise the brine could freeze into the pipes.

After the nitrogen freezing phase, the temperature of the copper pipes needs to be above -35 °C for the liquid brine to circulate, otherwise the brine could freeze into the pipes.